Jaw crusher is one of the earliest stone crushers in the world and is also the most widely used crushing equipment, which has the features of a simple machine structure, large crushing ratio, stable performance, easy to maintain and repair, etc.

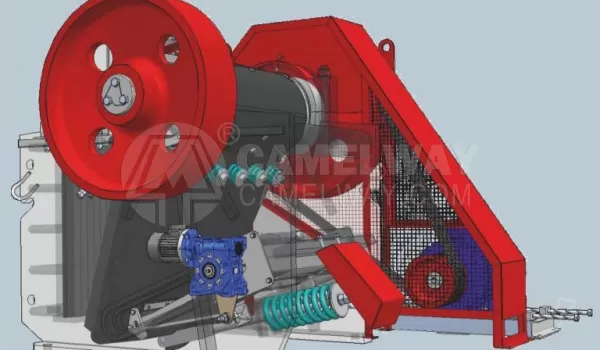

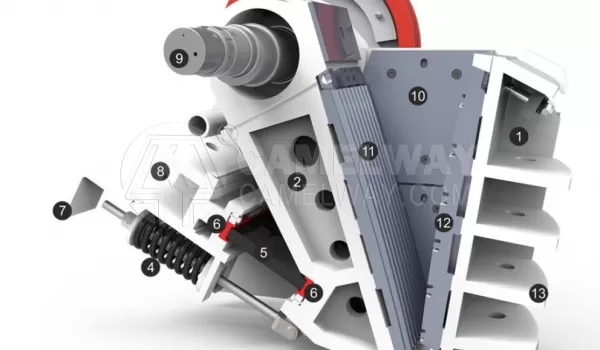

Jaw crusher mainly consists of rack, eccentric shaft, large belt pulley, flywheel, side guard plate, toggle plate, toggle plate backseat, adjusting screw, resetspring, fixed jaw plate and movable jaw plate. Jaw crusher adopts curled pressing method. Firstly, the motor drives belt and belt pulley, then eccentric shaft moves the movable jaw plate up and down. When movable jaw plate rises, the angle between it and toggle plate becomes larger, which pushes movable jaw plate to approach the fixed one. Raw materials will be multiply crushed through pressing, scrubbing and grinding of the two jaw plates; When movable jaw plate moves down, the angle becomes small and it will leave the fixture under the action of the pull rod and spring. With continuous operation of the motor, the movable jaw plate does crushing and discharging over and over again to achieve batch production.

PE Primary Jaw Crusher

PE / PEX series jaw crusher developed by our company is a type of single toggle jaw crushers, which is mainly used in primary crushing of hard, medium hard materiales and can provide the producing capacity of 1-2200 tons per hour. PE/PEW jaw crusher is usually applied in heavy mining, stone quarrying, sand & gravel crushing, recycling and other manufacturing projects.

PE Jaw Crusher Advantages

- It has the advantages of no key connection, strong rigidity, large rotor rotation inertia, high chromium plate hammer, strong impact resist ability, good wear resistance.

- Large feed port, high crushing cavity, comprehensive crushing function, high production efficiency. It can crush hard rocksand has a low abrasion which can guarantee high overall benefits.

- The products have a fine grain shape(near to cube), and the discharged products' granularity is adjustable, which can simplify the crushing process.

C Series Primary & Seconary Jaw Crusher

Compared with PE series jaw crusher, C series European type jaw crusher has a larger "V" type crushing chamber, which can crush larger stones and ensure crushing efficiency. Unlike PE series crusher, C series crushing machine adopts modular and no welded frame structure, so it can provide greater resistance to fatigue, reliability and convenient installation. Because of its unique characteristics, C series European jaw crusher is specially suitable for crushing pebbles, granite, iron ore, gold ore, copper ore and other high-hardness materials. Its maximum capacity is 845 tons per hour.

C series crushers are of the single-toggle type with a unique "V" type crushing chamber, which can let raw materialsenter into crushing chamber without any trouble so as to ensure the optimum feeding capacity. It can crush the hardest rock and ore, and obtain better performance when it is used to crush limestone, iron ore and other soft rock or recover slag under better working environment.

C Series Jaw Crusher Advantages

- Modular, no-welding frame structure

- Motive jaw wear well

- The whole cast steel bearing housing

- Crusher frame of repairable

- Efficient kinematics performance and strong power

- Provide appropriate jaw board for the specific application