The batching plant is a kind of high quality construction engineering equipment, its super high performance has been widely recognized by many customers, but we need to pay attention to some matters when starting, how much do you actually know about the information content of these aspects? Today we will describe in detail:

1. Close the main power supply, and the main power button is connected to the main power supply, and the indicator light is on.The bell rings to prompt the surrounding people to avoid the equipment. Usually, people should be 2 meters away from the equipment before starting. Do not stand under flat or inclined belt conveyors (avoid injury caused by falling idler during operation). Pay attention to whether there is anyone on or inside the blender and on the conveyor belt. If there is anyone, do not start.

2. Open the main switch of each branch power except frequency conversion operation, open the power supply of computer display screen, host machine and signal conditioner, and press any key on the keyboard to enter the page of equipment operation program when the enterprise interface appears. Press the control button of frequency converter to "off" and turn on the power supply of feeding belt operated by frequency conversion. Turn on the power to the screw conveyer and the water inverter controller on the cement bin. See if the ammeter indication is normally 380V±5%. Press the master starts button. Turnning on the air compressor and waits until the pressure is achieved.

3. When adding water, you need to turn the water frequency control knob to adjust the amount of water. Forklifts and excavators are prohibited from feeding directly without going through the hopper. Boulders in the aggregate bucket should be cleaned immediately.

4. Successively open: inclined belt conveyor -- agitator -- flat belt conveyor -- rotating 4 frequency conversion controlled feeding belt conveyor, cement frequency conversion screw (if automatic, press F1 key on the computer), waiting to be transferred to the corner of the belt conveyor open the water pump. When the machine is shut down, stop the material and cut off the water first, then turn off the power supply successively, and finally turn off the computer, signal conditioner and computer display screen.

5. Check whether the supporting roller does not rotate during normal discharging, and replace or maintain it immediately if there is any abnormality. Press emergency stop in case of personal safety. In general, do not press the emergency stop, because after pressing the emergency stop there is material on the belt, causing a backslide blocking agitator.

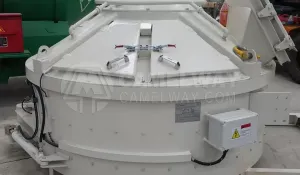

6. If the agitator falls off unexpectedly, the materials in the agitator must be cleaned and then restarted. Do not start the agitator with materials.

7. Aggregate falling is not enough, the belt speed ratio is too fast, which is very easy to dump, then you can open the big falling bucket. Blanking excess, the belt speed ratio is very slow, you can close the small blanking bucket.When using automatic, if the belt is running too fast due to empty material, press F1 key and then press F1 to open it.So you press F1 twice in a row.Use the vibrator as little as possible, the vibrator cannot be pressed for a long time, do not press the vibrator and empty material long press the vibrator when the feeding door is closed.

If you want to know more about the batching plant, please feel free to contact me. Bonnie Yang, mob: +86 17839193601, email: [email protected].