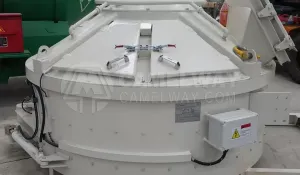

Twin Shaft Concrete Mixer Advantages:

- Ideal quality for the production of concrete products.

- Concrete homogeneity 92% in 40 seconds.

- High performance for production of ready-mixed concrete.

- Easy clean after mixing.

- Maintainability.

Our concrete mixers are four times cheaper than their European counterparts and certainly more reliable, due to the fact that there are no dubious technical solutions that Western colleagues hope to impress the buyer with.

Working principle of the JS500 twin-shaft concrete mixer.

The JS500 twin-shaft concrete mixer is a fixed body bolted to a frame. Inside the mix chamber there are two shafts rotating at 30 rpm. 7 levers are fixed on each shaft, with scraper tips equipped with replaceable protection (armor). Rotation is transmitted through a spur gearbox from a 18kW electric motor driven by a belt drive. The rotation from one shaft to the other is transmitted by the gear, which eliminates the rotation at different speeds and reliably prevents the lever from colliding.

In order to extend the service life of the concrete mixer, wear-resistant segment armor made of cast iron alloy, secured with a bolted joint, is installed on the inner walls.

Aggregate is supplied to the concrete mixer using a loading mechanism consisting of a skip, a winch driven by a 5.5 kW engine and guide rails. The skip has a bottom valve that allows the contents to be unloaded without overturning.