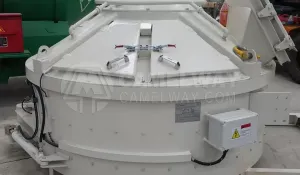

For more than a century, concrete has been the main material for construction, so the demand in equipment producing concrete mix has been growing. Concrete production is a difficult engineering task, therefore, every company manufacturing concrete mixing equipment is looking for ways to best solve this problem. The variety models of concrete batching plants that is offered to builders today allows us to make the best choice.

Concrete Batching Plant

Concrete Batching Plant also named as Concrete Mixing Plant, it is a completely self-sufficient production, which produces the required high-quality concrete for the needs of the industry. A concrete batching plant can have a variety of parts and accessories, including: mixers, cement batchers, aggregate batchers, conveyors, radial stackers, aggregate bins, cement bins, heaters, chillers, cement silos, batch plant controls, and dust collectors.

With the constant expansion of the city, commercial buildings, other infrastructure, the concrete batching plant is developing and applying quickly. With the gradual development of economy, the advantages of using concrete batching plant to produce concrete are further reflected.

1. Higher quality concrete

Thanks to various precise sensors and auxiliary control devices, the concrete batching plant can accurately control the concrete production process to ensure the highest quality of concrete, Meet the needs of various buildings.

2. Higher production capacity

Fully automatic production process, can produce a large amount of concrete in a short time, and can expand production capacity at any time according to demand.

3. Cost savings

At modern construction sites, labor costs and raw material costs account for a high proportion. Using a concrete mixing plant instead of manual mixing concrete can not only save labor costs, but also save raw material costs.

Application of Concrete Batching Plant

Concrete batching plants are overwhelmingly used in nearly all mega-building projects. If it’s about constructing roads, bridges, or buildings, the existence of a concrete batching plant holds the primary significance because it’s responsible for producing the concrete. Besides, Concrete Batching Plants are also used in the construction of civil engineering, ready mixing, and precast applications.

Concrete Batching Plant Types

There are many classification standards for concrete batching plants. Generally speaking, they can be divided into mobile batching plants and stationary batching plants. Some manufacturers also have their own derivative classifications. However, the principle of concrete production in concrete batching plants are same. Therefore, if you are planing to purchase a concrete batching plant, just contact the manufacturer directly, a capable manufacturers can tailor the equipment.

About US

Camelway is an old and experienced construction equipment manufacturer. Founded in 1983, our concrete batching plants operate in more than 100 countries around the world.