Jaw Crusher is the most commonly crusher used for primary crushing, it has two types Single toggle and Double Toggle.

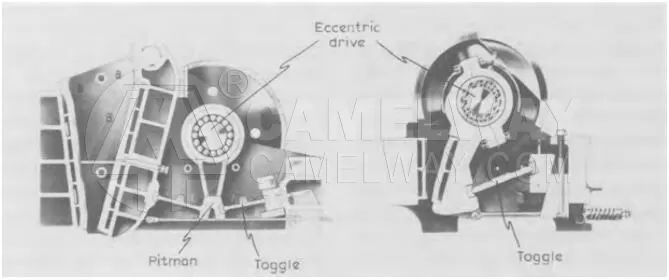

In the double toggle crusher the rotation of an eccentric shaft causes a vertical reciprocating motion of a component called a pitman that is translated by two toggles into swinging action of the moving jaw which is pivoted at its upper edge. The resultant action creates very powerful compressive forces by leverage in the upper zone of the crushing chamber and the almost total absence of abrasive motion (relative vertical motion between jaw plates). Therefore, this machine is most applicable to the crushing of very strong, abrasive rocks but is more complex, heavy and expensive than a single toggle crusher.

In the single toggle machine the moving jaw is actuated by an eccentric shaft which also acts as the pivot along the upper edge of the jaw. The resultant action includes relative vertical motion between the jaw plates which produces the advantage of greater throughput for less abrasive rocks. In both cases the jaws are protected by replaceable alloy (manganese steel) liner plates which may be smooth or corrugated to reduce the production of slab shaped particles. The jaw crusher is suitable for all hard rocks generally used for aggregate.