The stone sand production line is to process large stone into sand materials of different grain sizes. Usually, according to the different output requirement, the equipment types are different. Different equipemts are get together to makes up different production lines. Which devices do you need to use in the stone sand production line.

First, the crushing equipment If the stone raw material is relatively large, it may not be able to meet the operation of the sand making equipment, so it is necessary to use the jaw crusher equipment. In the selection of the fine crushing equipment, the cone crusher or the counter crusher can be used to crush the sandstone raw materials. The treatment, so that the size of the gravel material after the fine crushing treatment also meets the operation requirements of the sand making equipment.

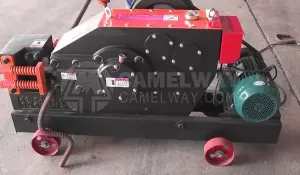

Second, sand making plant When selecting sand making equipment, VSI sand making machine and impact sand making machine can be selected. In addition, some users are limited in construction, and mobile sand making equipment can be selected. The equipment can move freely according to the construction site. No requirement, no need for fixed installation, it can complete sand making of sand and gravel materials.

How to choose the sand production line?

First, when buying ore crushers, users should first check the details about the crusher information, a general understanding of the shape, structure and working principle of the equipment.

Second, the appearance of the ore crusher should be checked. The appearance of a good ore crusher is relatively neat, and there is no pit and smash on the surface. The weld seam is also required to be smooth and flat, they can never be good manufacturers if they can't make a good appearance of the sand crusher.

Third, the internal parts of the sand crusher should be inspected in detail, because the appearance of the crusher is roughly the same. The quality of the equipment itself depends on the quality of the internal parts. The good internal parts can be effectively extended, and the equipment usage time and production efficiency will be increased.