Ideally, both the aggregates and the cement would be completely dry, so the amount of water required for each batch would be a set volume and the quality of the concrete produced would be identical batch after batch. However, aggregates are typically stored in a stockpile, usually outside, and although good storage can help, even for materials stored in covered bins the moisture held in the aggregates will be in a constant state of change due to the inevitable effects of drainage.

In modern concrete batching plants the amounts of materials required for the recipe are typically weighed and the recipe is calculated using the assumed ‘dry’ weight of the materials. However, within the weighed aggregates there will be an unknown amount of water. Surplus water or moisture content in the sand and aggregates can also have dramatic effects on the water/cement ratio, the aggregate/cement ratio, the yield and the colour of the mix. This will lead to inconsistencies in slump, strength, colour and quality, resulting in an inferior end product.

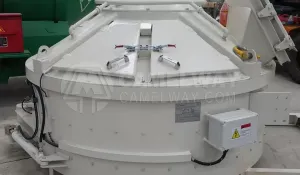

In order to make the good quality concrete products every day it is vital to maintain a consistent moisture content in the concrete mix. Many years ago before technology was available this was done by testing each batch by hand. The batching plant operator would normally take a hand full of mix while the mixer was running and squeeze making a concrete ball in his fist to feel and determine to determine the correct moisture content. Typically, in the morning the mix requires less water to be added in each batch and in the afternoon the sun and heat dry’s the aggregates requiring more water to be added to the batch of concrete mix. The hand moisture concrete testing process is an art that is very similar to a chef learning the feel and look of making the correct dough consistency for cakes, breads or pizza.

Then in the later 1960’s, 70’s, 80’s technology tried to replace the human element with devices to add water control moisture consistency automatically within the mixer. In most applications the meters and systems would work satisfactory but were not totally reliable with all types of different sand, rock, lightweight of heavy weight materials and heat differences in aggregates. In the last two decades’ technology has made huge advancements that have proven to be extremely accurate and reliable by introducing Microwave Technology. With the introduction of the Microwave moisture meter probes, sensors and programming to control these systems the concrete industry has made huge innovations. This is done by using sensors that utilize digital techniques for measuring the change in a microwave resonator frequency with changes of moisture in the material. Possibly the most important factor is that this technique provides a greater accuracy of measurement over a far wider range of moisture contents, and is suitable for working with a far wider range of materials provide a superior accuracy in repeating the required amount of water needed in your mix. To add even greater accuracy probes can be put in mixers and also the aggregate bins for even greater consistency which allows producers to maintain within 2% of your target moisture content using this type of system. This saves you money in cement, quality control, labor savings, loss of any bad products and any hauling charges and much more.