Seven Major Systems of Concrete Batching Plants

Concrete Batching plants are intricate assemblies comprising numerous components, amalgamating storage, conveying, weighing, and mixing functionalities into a unified equipment ensemble. Despite their multifaceted nature, with over a thousand scattered parts, to facilitate discernment, we uniformly categorize concrete Batching plants into seven major systems. These systems collaborate harmoniously to ensure optimal operation. Let's delve into each of these seven systems:

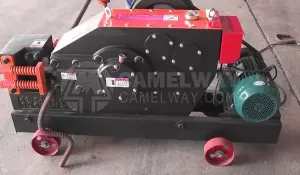

Mixing System:

The mixing system is the heart of the concrete Batching plant, responsible for blending various aggregate materials, cement, water, and admixtures to produce homogeneous concrete mixtures. It typically includes mixers, mixing blades, and discharge mechanisms to facilitate thorough mixing.

Weighing System:

The weighing system accurately measures and controls the proportions of aggregate materials, cement, water, and admixtures to achieve precise concrete mixtures. It comprises load cells, weighing hoppers, conveyors, and batching controls to ensure consistency in batch proportions.

Storage System:

The storage system encompasses silos, bins, and tanks for storing bulk materials such as aggregates, cement, and admixtures. These storage facilities ensure a steady supply of materials for continuous production.

Conveying System:

The conveying system transports materials between various components of the concrete Batching plant, such as from storage bins to weighing hoppers or from the weighing system to the mixer. It includes conveyors, belt scales, and pneumatic systems for efficient material transfer.

Pneumatic System:

The pneumatic system controls the flow of air and other gases within the concrete Batching plant, facilitating operations such as material transfer, dust collection, and pneumatic conveying. It comprises compressors, air valves, and pneumatic actuators to regulate airflow.

Electrical System:

The electrical system provides power and control to the entire concrete Batching plant, encompassing power distribution, motor control, and automation components. It includes transformers, switchgear, motor starters, PLCs (Programmable Logic Controllers), and HMI (Human-Machine Interface) panels for efficient plant operation.

Dust Collection System:

The dust collection system ensures environmental compliance and worker safety by capturing and controlling airborne dust generated during material handling and mixing processes. It comprises dust collectors, filters, and exhaust systems to mitigate dust emissions and maintain air quality.

These seven systems work in tandem to facilitate the efficient and reliable operation of concrete batching plants, ensuring the consistent production of high-quality concrete for various construction applications.