The electrical system and control system play a crucial role in large concrete batching plants, responsible for managing and monitoring various process flows to ensure the efficiency and quality of concrete production. Below is a brief introduction to the electrical system and control system of large concrete batching plants:

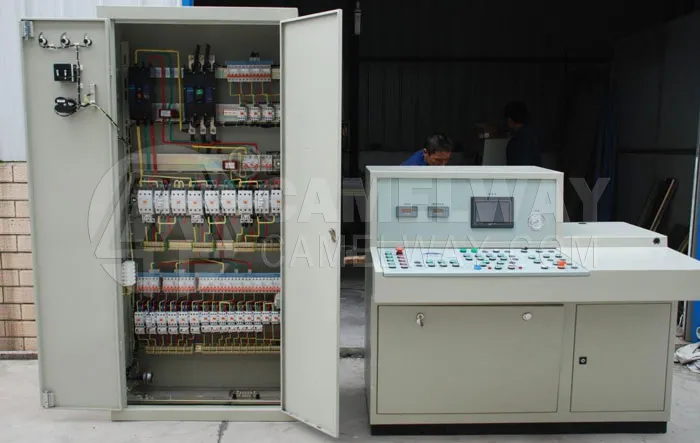

Electrical System:

- Power Supply System: Consists of power transmission lines, transformers, and distribution cabinets, providing stable power supply to the mixing plant.

- Power System: Comprises motors and transmission devices that drive concrete mixers, conveying equipment, etc.

- Lighting System: Provides interior and perimeter lighting facilities to ensure a safe working environment.

- Control Equipment: Devices used to control and monitor the operation status of various electrical equipment, including contactors, circuit breakers, relays, etc.

Control System:

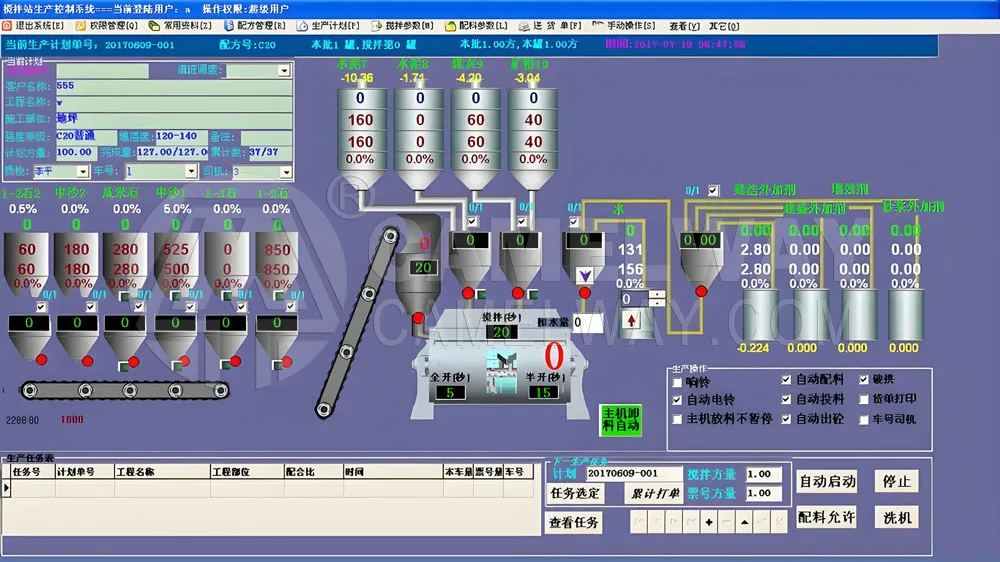

- Automatic Control System: Large concrete batching plants are typically equipped with automatic control systems, which complete the production process automatically based on preset programs and parameters to ensure consistency in production efficiency and product quality.

- PLC (Programmable Logic Controller): As the core of the control system, PLCs receive and process signals from sensors, switches, etc., and control various parts of the mixing plant based on preset logic and algorithms.

- Human-Machine Interface (HMI): Through touch screens or other interfaces, operators interact with the control system, monitoring production parameters, making settings and adjustments, and receiving alerts and fault diagnostic results.

- Sensors and Instruments: Used to monitor temperature, pressure, flow rate, and other parameters at various parts of the mixing plant in real-time, transmitting data to the control system for analysis and processing.

The design and operation of these systems directly impact the production efficiency, energy consumption, and product quality of concrete batching plants. Therefore, when planning and constructing batching plants, the stability, reliability, and flexibility of these systems need to be fully considered. The electrical control system has been upgraded, adding the following features:

- The system is developed under the Windows XP system, featuring multitasking, multi-window, and multi-user control capabilities to enhance overall system performance and application flexibility.

- Dynamic simulation of the entire production process is displayed in real-time, with a user-friendly operating interface for easy operation and maintenance.

- Intelligent under-weighing compensation and over-weighing deduction are implemented during material batching, weighing, and unloading processes to improve weighing accuracy and production efficiency.

- Dynamic comprehensive evaluation and compensation of material batching errors are achieved to reduce material measurement errors during production, increasing economic benefits.

- Control screen is divided into functional areas for production, management, and inspection, facilitating the transition from production mode to management mode, and enabling monitoring and management of the production process.

- A safety operation mode is provided to effectively prevent accidents caused by misoperations.

- System administrators can assign login passwords to each operator and set operating permissions to ensure system security.

- Each operation by operators automatically generates operation logs, recording operation information for traceability and analysis.

- The system has automatic fault reminder and alarm functions to improve the stability and reliability of equipment operation.

- Reserved sewage windows, ERP interfaces, and board expansion ports are provided for convenient system upgrades and expansions in the future.

Although the electrical control system has been upgraded, it should be flexibly selected according to the scale and requirements of concrete batching plants. It is recommended for use in large concrete batching plants, while standard configurations can be chosen for medium and small concrete batching plants.