Hot mix asphalt facilities can be broadly classified as either drum mix plants or batch mix plants, according to the process by which the raw materials are mixed. In a batch mix plant, the aggregate is dried first, then transferred to a mixer where it is mixed with the liquid asphalt. In a drum mix plant, a rotary dryer serves to dry the aggregate and mix it with the liquid asphalt cement. After mixing, the HMA generally is transferred to a storage bin or silo, where it is stored temporarily. From the silo, the HMA is emptied into haul trucks, which transport the material to the job site.

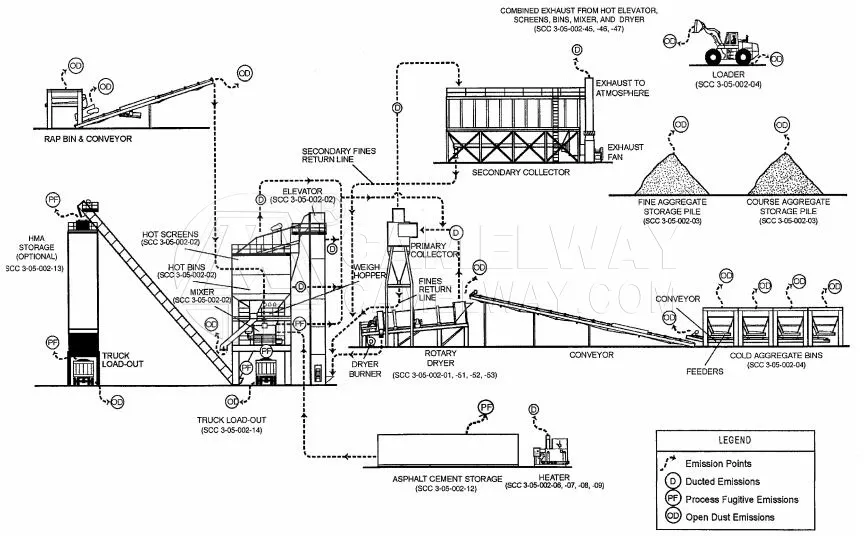

Batch Mix Plant

Processing begins as the aggregate is hauled from onsite storage piles and is placed in the appropriate hoppers of the cold feed unit. The material is metered from the hoppers onto a conveyer belt and is transported into a rotary dryer (typically gas- or oil-fired). As the hot aggregate leaves the dryer, it drops into a bucket elevator, is transferred to a set of vibrating screens, then separated into as many as four different grades (sizes), and dropped into “hot” bins according to size. At newer facilities, RAP may be transferred to a separate heated storage bin. At the same time, liquid asphalt cement is pumped from a heated storage tank to an asphalt bucket, where it is weighed to achieve the desired aggregate-to-asphalt cement ratio in the final mix. To control the aggregate size distribution in the final batch mix, the operator transfers material from various hot bins (and RAP bins, if used) to a weigh hopper until the desired mix and weight are obtained. The aggregate from the weigh hopper is dropped into the mixer (pug mill) and dry-mixed for 6 to 10 seconds. The liquid asphalt is then dropped into the pug mill where it is mixed for an additional period of time. At older plants, RAP typically is conveyed directly to the pug mill from a storage hopper and combined with the hot aggregate. Total mixing time usually is less than 60 seconds. Then, the hot mix is conveyed to a hot storage silo or is dropped directly into a truck and hauled to the job site.

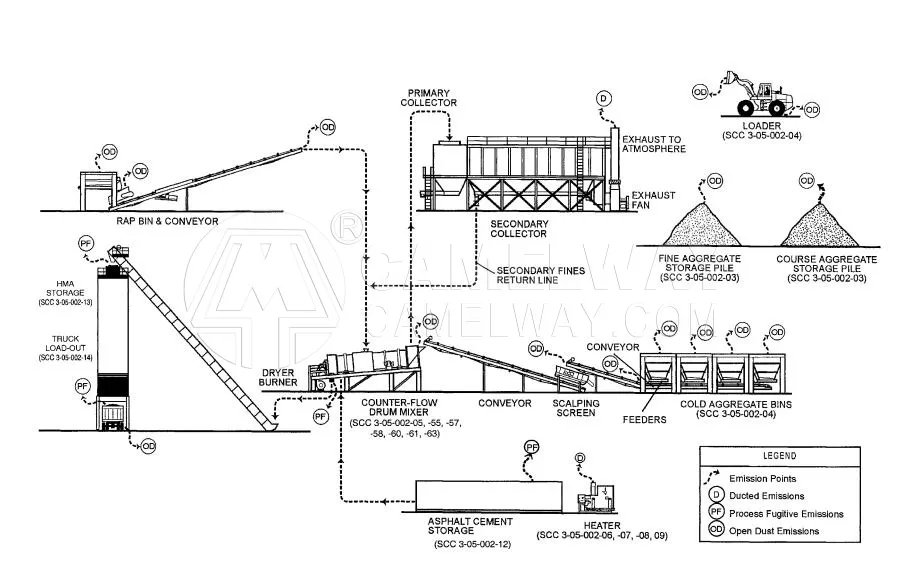

Drum Mix Plant

This process is a continuous mixing type process. The major difference between this process and the batch process is that the dryer is used not only to dry the material but also to mix the heated and dried aggregates with the liquid asphalt cement. In a parallel flow drum mixer, the aggregate is introduced to the drum at the burner end. As the drum rotates, the aggregate, as well as the combustion products from the burner, move toward the other end of the drum in parallel. Liquid asphalt cement is introduced in the mixing zone midway down the drum in a lower temperature zone, along with any RAP and PM from collectors. In a counterflow drum mixer, the material flow in the drum is opposite or counterflow to the direction of exhaust gases. In addition, the liquid asphalt cement mixing zone is located behind the burner flame zone so as to remove the materials from direct contact with hot exhaust gases. After mixing, the mixture is discharged at the end of the drum and is conveyed to either a surge bin or HMA storage silos

In a parallel flow mixer, the exhaust gases also exit the end of the drum and pass on to the collection system. Parallel flow drum mixers have an advantage, in that mixing in the discharge end of the drum captures a substantial portion of the aggregate dust, therefore lowering the load on the downstream PM collection equipment. For this reason, most parallel flow drum mixers are followed only by primary collection equipment (usually a baghouse or venturi scrubber). However, because the mixing of aggregate and liquid asphalt cement occurs in the hot combustion product flow, organic emissions (gaseous and liquid aerosol) may be greater than in other processes.

Counterflow drum mix plants likely will have organic stack emissions (gaseous and liquid aerosol) that are lower than parallel flow drum mix plants because the liquid asphalt cement, virgin aggregate, and RAP are mixed in a zone removed from the exhaust gas stream. A counterflow drum mix plant normally can process RAP at ratios up to 50 percent with little or no observed effect upon emissions.