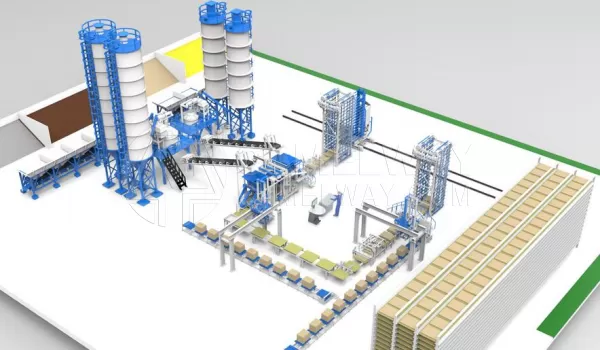

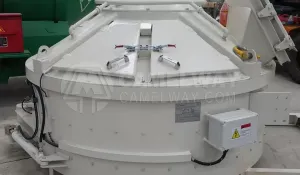

Camelway's Stationary block making plant are high-quality equipment for the production of borders, pavers, blocks, high-quality insulation blocks, etc. The flexibility of the configuration, as well as the presence of a large number of components and assemblies, makes it possible to make a modular block line . Flexible pricing allows you to produce very simple models, using manual labor, to high-quality, fully automatic computer-controlled plants. We provide a free full set of spare parts!

How consistent is the height control of your blocks during production?

It is vital to have good height control on building blocks in the Chinese market and many other markets throughout the world. In some areas of the China it is very common to consistently maintain each individual height of the building block during manufacturing to be within 1/16” or 1.58 mm.

How many blocks can a machine make?

It is very important to understand the difference between how many blocks are made per cycle in a building block machine and how many are made per hour. Sometimes a machine may make more per cycle but make less per hour because the cycle time is so slower in the larger output machine. When comparing machines, more blocks per cycle does not always mean better production at the end of the day.

It is important to ask first what size block we are talking about. The smaller the building blocks size the more units we make in mold working area and per cycle. The smallest machine I offer makes one 8”x8”x16” (20x20x40 cm) hollow core building block per cycle. The largest machine I offer makes fifteen 8”x8”x16” (20x20x40 cm) blocks per cycle. I supply machinery systems that can make between 1000 and 28,800 8”x8”x16” (20x20x40 cm) per 8-hour shift.

I want to make a specific product and need to see if your machines can make it?

This is a very common question since so many of my customers have used my machinery systems to create new products. This is because we listen and adapt our standard machines with changes to meet your needs.

This process is started by your sending me a picture or two dimensional sketch of the product you what to produce. I will call you back to discuss the overall details. We will talk in more detail the specific concepts of the product, strength requirements, materials you want to use in making the product. Other questions normally talked about are dimensional tolerance of the product and production output requirements. Within a week I will be forward to you details on pricing and what equipment is required to manufacture and produce your product.

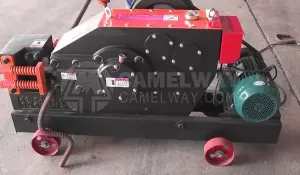

How much maintenance does it take to operate a plant?

This can vary widely of course with the products you are producing and what level of automation you have chosen in your operation. My general rule is for every 40 hours run time you need to have 8 hours’ preventative maintenance time. That means during each day you still have to do the daily tightening of bolts, greasing, check oils and cleaning of machinery.

At the end of the week, normally on a Saturday you would have two people come into the plant for four hours (half day) to checks details that are not part of the daily checklist.

The two maintenance people would be doing the weekly & monthly checklists on all the equipment. This would include examining every inch of the machinery and doing detailed inspections. By doing these weekly procedures, it will greatly reduce your risk of any downtime during the weekly production runs.

Preventative maintenance will make you money. You need to fix the problems correctly and not just put a Band-Aid or quick fix on the problem. The time will come when all those small quick fixes will cause you to lose a lot of money and you will not be able to grow your business. Remember you must have good procedures and people to make a concrete products plant success!