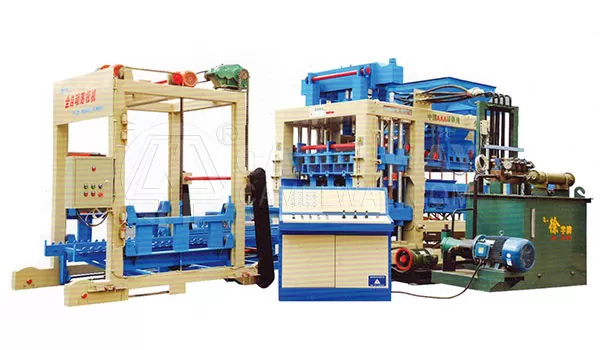

QT8-15 Automatic Vibrating Press is one of the reliable, proven on the positive side vibrating presses with an automatic control system. Proposed vibrating press is capable of producing both wall products (brick, block, partition blocks), and road products of excellent quality (paving slabs, curbs, landscaping elements).

The solutions offered by us, which include both individual elements and complex solutions, in their overwhelming majority are as much as possible eliminated from the presence of expensive auxiliary control nodes and complex electronic control systems; this eliminates the need for long-term fine and deep adjustment of the press to achieve the desired result.

Do you supply block molds?

Yes, We supply molds for most any block machine made in the market. All We need to know is the exact brand name of the machine, model number and product pallet dimensions. In addition, you just need to send me a two-dimensional sketch, product illustrations or pictures of the unit you want to make. We will normally will call you back with a few questions and you will be able to receive a mold offer from me within a few days.

How long does a mold last?

There is no one perfect number that can answer this question. Many factors go into determining this, such as the following top five:

- Hardness of aggregates you use to make your concrete specific units.

- How the operator secures, installs and sets up the mold in the block machine.

- The amount of vibration time programmed into the machine cycle.

- The density and tightness of the product you are trying to produce.

- The product quality and tolerance standards allowed by the producer.

How long does it take to change molds in a machine?

There are two factors when you change a mold. One is the physical time it takes to replace the mold in the building block machine. The second is how long it takes to be operating making good products once that mold has been changed.

A typical mold change time also depends on whether you are changing molds that are making the same or a different height product already set up in the block machine. For example, changing a building block mold to a same height building block mold is much faster than changing a building block mold (taller) to an interlocking paving stone mold (less height).

It depends on the level of machine system we are talking about but in general the following applies:

- Same height to the same height mold change can be as fast as 5 minutes.

- Different mold height changes as fast as 15 minutes.