QT3-15 is one of the reliable, proven on the positive side of vibrating presses with a semi-automatic control system. This vibrating press is capable of producing both wall products (brick, block, partition blocks), and road products of excellent quality (paving slabs, curbs, landscaping elements).

Features and specifications:

- Hydraulic semi-automatic control and manual control, automatic feed and stacking.

- Using the force feed device, you can quickly and symmetrically feed raw materials.

- Special design for the manufacture of pavers: the ability to automatically feed material from the surface.

- Good quality frame, ease of use, repair and cleaning.

| Vibration frequency | 3800-4500 (beats / min) |

| Vibration Strength | 68KN |

| Molding Cycle | 15-20 (s) |

| Pallet Size | 680 * 540 * 20 (mm) |

| Overall dimensions | 5130 * 3850 * 2600 (mm) |

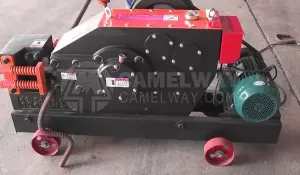

The Qt3-15 cement hollow block semi-automatic molding vibration press is equipped with touch screen computer. The perfect control system allows you to fully automate and intellectualize the production process, including mixing, material feeding and compression molding.

The machine for the automatic formation of cinder blocks is made of heavy-duty structural steel using special welding equipment and welding materials. In this installation, imported engines, sealing elements and hydraulic elements are utilized. Therefore, it is durable and resistant to shock. That is, our car is stable and reliable.

In addition to the elongated sliding sleeve, four guide columns are used to accurately move the mold. A synchronous top link device is used.

Our cinder block molding machine uses a large hydraulic pressing device. Thus, it can produce heavy bricks with a maximum density of up to 20MPa. Finished products have such advantages as compactness, exact size and shape.