Mobile Block Making Plant consist two parts, one is a concrete mixing plant, another is a mobile block making machine. Camelway offers both of them as a total mobile concrete block production solution. Mobile block making plant can use to produce hollow and solid block. Usually, Mobile Block Making Plant uses the HZS25 Concrete Batching Plant as a Concrete Production Equipment, JMQ series mobile block making machine to produce blocks.

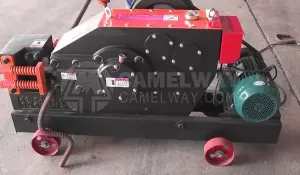

Mobile Block Making Machine is hydraulic type, has higher pressure, thus the product quality is good. This Block Making Machine is mobile, no need pallet, so it can save a lot of money. Unlike stationary machines, Mobile Block Making Machine can be used at anywhere that is flat. Besides, this block machine has a storage hopper to store mixed concrete, very convenient in use, which can automatically feed concrete material into the mould box. This Block Making Machine has a seat for the operator. Operator can sit there, control the production process and moving, very personal design.

| Model | Block Size | Production Capacity |

| MP-6A | 400*200*200mm | 540-720 pcs/hour |

| MP-6A | 400*150*200mm | 720-960 pcs/hour |

| MP-6A | 400*100*200mm | 990-1320 pcs/hou |

| MP-4A | 400*200*200mm | 250-325 pcs/hour |

| MP-4A | 400*150*200mm | 300-400 pcs/hou |

| MP-4A | 400*100*200mm | 420-570 pcs/hour |

| QTR2-45 | 400*200*200mm | 2 pcs/mould, 160 pcs/h |

| QMD4-45 (Diesel Engine) | 400*200*200mm | 1600-2100pcs/8hrs |

Portable block machine for job site

We have a portable machine system that can produce both block and interlocking pavers. It can be powered by a single-phase electrical motor or by a gasoline powered engine. The portable machine systems can be offered as an individual machine system. I also have available completely portable plants that are mounted on trailers or in containers and can be taken to the job site.

FAQ

What Materials are used to make Building Blocks?

Concrete Masonry Units (CMU) are made of a proportioned combination of powdered Portland cement, water, sand, and gravel. This produces a light colored gray block with a fine surface texture and a high compressive strength. A typical concrete block 8”x8”x16” (20x20x40 cm) weighs 38-43 lbs. (17.2-19.5 kg). You can also make the CMU in different colors by adding Iron Oxides colors into the mix or by using a white cement to change the color of the CMU’s.

What size sand and rock does it take to make block?

The most commonly used size of aggregate (rock) is 3/8" (9.5 mm) and sand sieve size is #8 (2.36 mm), which is extremely import to have the correct amount of blended materials not only to make and strong product but also a profitable unit with the texture you require.